24 Sep Safe handling of EV

Figure 1_Jaguar E-Pace charging (Pole AC 7,4 kW) in Montornes, in the Metropolitan Area of Barcelona.

It is well known that the proliferation of the Electric Vehicle (EV) is going to make great changes in many aspects, not only in the automotive or transportation industry of urban environments, and gradually in rural areas, but also for the daily life of the EV and road transport users in general.

Evidently, and parting from the urgent necessity of improving the quality of the air in the metropolitan area, reducing the global emissions and oil imports, with the consequences that brings in terms of dependence on third countries, sometimes those conflicts lead their populations to an exodus in order to save their own lives. We must understand the EV as a great opportunity at an industrial, sustainable and economic level. In terms of sustainability, to reduce emissions, and at industrial and economic level, a possibility of environmental improvement as well as a technological implementation. Furthermore, the possibility of launching a brand-new method for the automotive and transportation industry. Even more speaking of a country like Spain, which is the second largest producer of cars and the first in industrial vehicles in Europe.

To accelerate the implementation of the EV, it is mandatory to work close with all the sectors involved, EV and charging infrastructure manufacturers, transport operators, fleet managers of public or private companies, such as the technical assistance service and the final users, along with the Public Administration.

Regarding the assistance service specifically, the EV is going to affect in what until now we have known as the Technical Assistance or Car Dealers, since the business model so far known in terms of vehicle maintenance, which has brought great benefits to car OEMs and its partners. This current situation will change when most cars are electric, considering that the maintenance of an EV is substantially reduced compared to the Internal Combustion Vehicle (ICV) may have, because is not mandatory to change oil, filters, etc., every few km. On the other hand, regarding the power electronics and the electric motor of the EV, they are practically maintenance-free. The electric engine has been in the industry for over 100 years, it is highly evolved and nowadays it has been greatly improved to make it work without any maintenance. In addition, just to clarify, the EV merely requires any upkeep just the basic, such as changing tires and lighting system, among others.

This blog will present an introduction of what is the main action to consider in terms of occupational risk when the technicians of the Service must work with EV. This labor basically consists of the disconnection and connection of the high voltage (HV) system.

Figure 2_Nissan Leaf version I in the Smart City Congress, Barcelona.

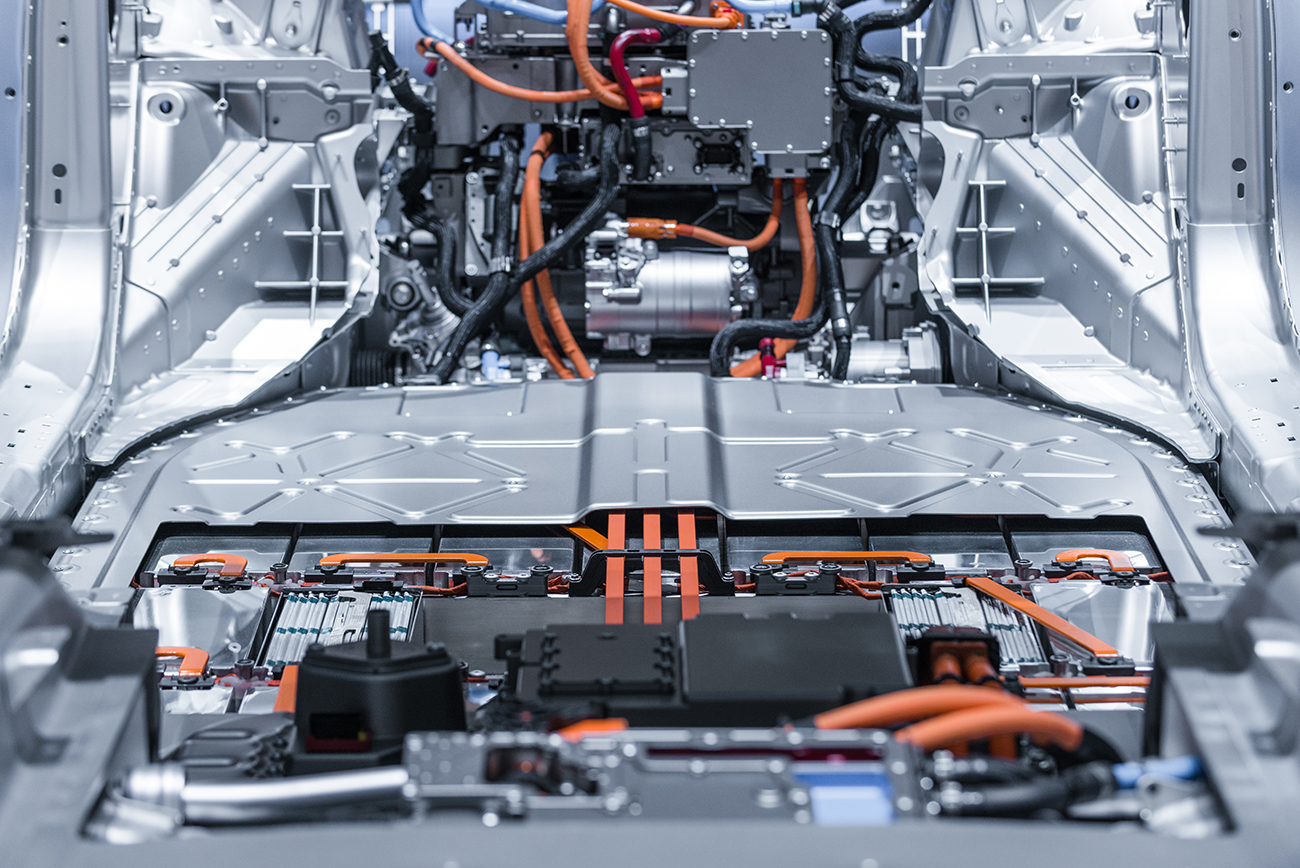

In order to carry out those operations; connection and disconnection of the HV system, it must be clear to know when the HV system is active in the EV. That means, when the HV system supplies the power train (Electric Engine and Power Electronics) and the compressor of the Air Conditioning by activating the HV switch, that at the same time connects the battery pack to the Power Train. Likewise, other possibilities for the connection and disconnection of the HV system can be made by the Control Pilot, by the activation of the Airbag in case of accident, or the simple activation by the ignition key of the EV.

Subsequently, although the vehicles themselves incorporate insulation resistance measurement systems between the live parts and the rest of the automobile. It is crucial to know what is the concept of the electric isolation is and which are the standards that regulate it both in the Automotive Industry (ECE R-100, Uniform provisions concerning the approval of vehicles with regard to specific requirements for the electric power train), and in the Electric Industry (e.g.: IEEE 43-200, IEEE Recommended Practice for Testing Insulation Resistance of Rotating Machinery). Due to the fact that the technicians who will carry out the interventions in the EV and the Electric Vehicle System Equipment (EVSE), will also carry it out in the charging systems (EV’s), the latter governed by electric standards.

Talking about the process itself to work with the disconnection and connection of the HV. First, the disconnecting process of the HV in the EV must be effectuated, just to ensure the safety of the technicians. Whenever possible, the job will be made without a voltage supply, for both, the ancillary low voltage battery, and for the high voltage battery pack. Battery Pack.

To achieve the most important steps: the disconnection and the connection of the HV in the EV, it is necessary to cordon off de vehicle from the Internal Combustion Vehicles (ICV). To execute this, it is compulsory to use signs and use places in the workshop somewhat apart from the rest of the workplaces, to isolate the area and achieve greater safety, clearly indicating “DANGER” – Keep out – Hazardous voltage inside may cause severe injury or death. At the same time, the Car key and the Service Disconnect or maintenance connector, must be kept in a safe place. Once it has been disconnected and letting the EV some seconds to stabilize in terms of Voltage (it is always convenient to let the vehicle cool a few minutes after removing the Service Disconnect or maintenance connector).

Figure 3_Left, example of a Service Disconnect or maintenance connector. Right, disconnection of the Service Disconnect or maintenance connector from the BMW i3.

After performing the indicated steps, the next and very important step is the verification of the absence of voltage in the vehicle. In other words, check if the high voltage system supplies the rest of the EV (power train and air conditioning compressor). Not to mention that all those steps and the complete process must be written in the Service History of the EV.

After the maintenance connector disconnection, it is necessary to check the resistance between the ground bolt mating surface and the high voltage harness connector flange of the battery pack, which has to be close to O ohms.

Later, it is feasible to check the insulation resistance of the battery pack, of course, using the appropriate devices for such measurements. For electrical engineering, it is possible to find devices for measuring the insulation resistance in cables or rotatory machines. Nowadays, it is plausible to find some devices designed exclusively for the insulation resistance measurement in EV, being of course, more expensive than the generic ones. In those measurements, comparing the results obtained in the measurement with what is indicated by the standards is required, in order to determine if the measurement indicated by the multimeter is appropriate to ensure the properly insulation of the battery pack regarding the vehicle body.

After that, and if the previous operations have been made properly and following the instructions, the next steps can be executed harmlessly, including battery extraction itself to verify the modules, the cells and other components of the battery pack (fuses, contactors, insulation board and others).

Figure 4_Exemple of cells type Soft Pouch in modules of the battery pack in a Renault Zoe.

Subsequent to these tasks that the vehicle without voltage requires, it is feasible to connect the high voltage in the EV.

To reconnect the high voltage system, first, the service disconnect must be inserted in order to reconnect the high voltage again.

Once a few minutes have passed after the maintenance connector has been connected, it is possible to proceed with the diagnosis of the EV, reading and erasing any possible errors.

As a last step, and before finishing all the process, we must perform an insulation measurement by indirect measurement with the EV connected to the high voltage, to verify if when inserted the service connection there is a lack of insulation.

If all that has been checked previously is correct, this process can be terminated safely.

Last but not least, the PPE (Personal Protection Equipment), which must be the correct, both, in choice and in maintenance, among these would be; insulating gloves, face shield, 1000 V insulated tools, personal protection equipment, including insulated boots, and even, not strictly necessary but recommended, the insulating blankets. The maintenance of all the mentioned, that can be equal or more important than the same disposition of the PPE.

JSR – Consulting conducts training for Technicians in the Automotive and Transportation industry in general to work with High Voltage Systems in a safe manner.